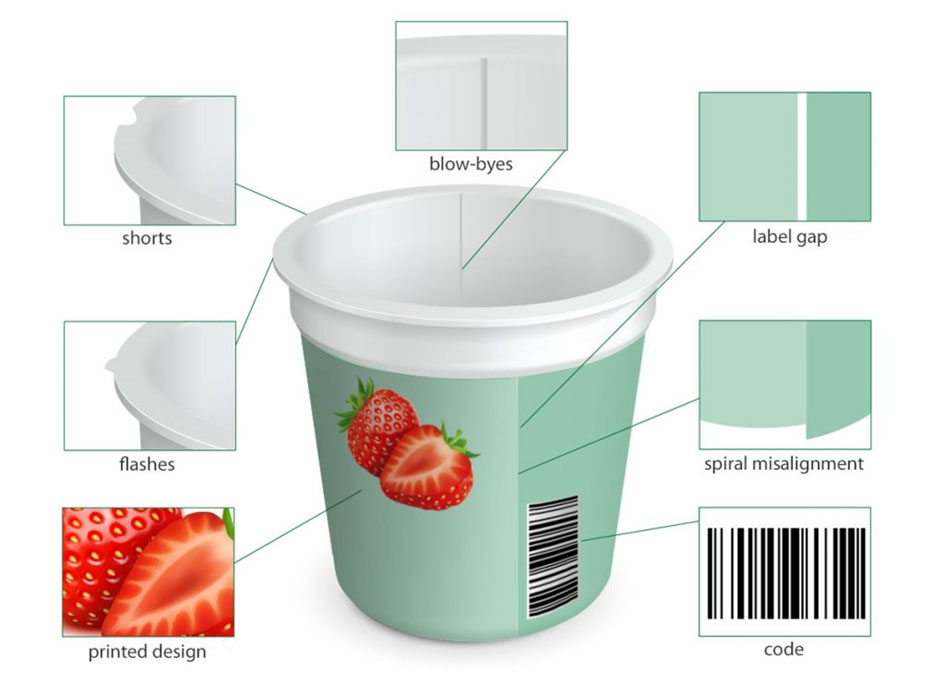

In the in-mold labeling (IML) process, the label is placed in a mold and liquid plastic is injected. The result is a product in which label and product are permanently bonded.

In-mold labeling is used for a wide variety of food packaging, such as yogurt, ice cream or cream cheese, but also for paint buckets or detergent bottles.

Thanks to many years of experience in the quality control of IML products, mevisco camera systems are optimally adapted to the needs of IML production.