The tooling used for plastic injection molding is called a plastic mold or plastic injection mold. The plastic mold is made from a combination of steel plates and other mold components, coupled to form an overall mold, which is then reliably assembled and installed in an injection molding machine, then applies a thermoplastic resin to the desired shape to fulfill the intended purpose.

Most plastic products are molded by plastic molds.According to the molding plastic characteristics, plastic molds are divided into thermosetting and thermoplastic mold.

By its very nature, an injection mold must satisfy a multitude of demands simultaneously when the molding process is being conducted. To form a plastic component having the shape of the mold cavity, the mold must contain the polymer melt inside the mold cavity. Heat is transferred from the hot polymer melt to the cooler mold steel, in order to give injection molded products as uniform and cheaply as possible. Lastly, the mold produces a fairly repeatable ejection of the part, which makes subsequent moldings more efficient.

GET A FREE QUOTE-30% LOWER ,15 DAYS LESS

The injection mold is expected to perform these three functions – contain melt, transfer heat, and expel molded parts – as well as additional requirements. Taking the example of containing polymer melt within a mold, it is imperative to have the mold resist enormous forces that may deflect or open the mold, and it must contain a feed system that directs the polymer melt from the molding machine to one or more cavity in the mold.

Additionally, these secondary functions can give rise to tertiary functions when specific mold components or features are used to accomplish them. Injection molds perform a number of functions, but they should be considered only a sample of the necessary primary and secondary functions during the design phase. Even so, a skilled designer would recognize when different functions are putting conflicting requirements on the mold design. Multiple cooling lines that are tightly spaced can provide efficient cooling by conforming to the cavity of the mold.

When it comes to removing parts, ejector pins may be required at locations where cooling lines are not desired. Designing a mold in a way that satisfies the conflicting requirements is the responsibility of the mold designer. When in doubt, novice designers tend to overdesign. The tendency to do so often leads to large, inefficient, and costly molds.

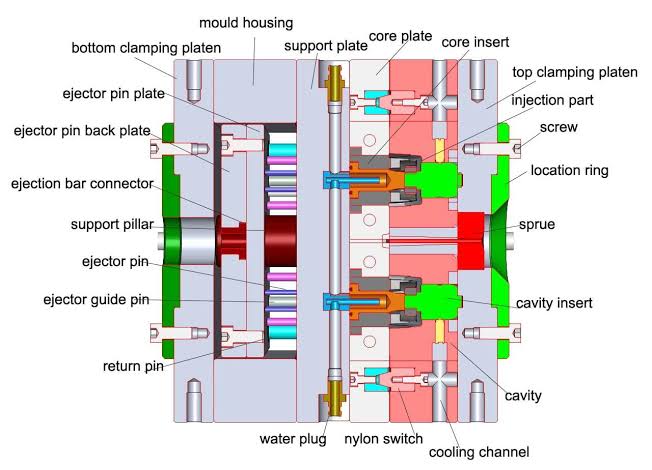

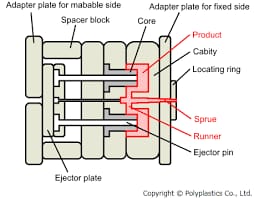

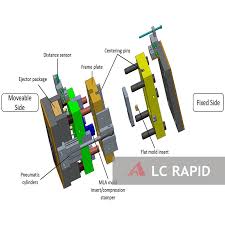

The Structure Of An Injection Mold

Injection molds come in all sorts of structures, from 2-plater to hot runner molds depending on application and design requirements, but most typically consist of these elements:

Mold bases Mold bases offer secure and accurate foundations for molds. The mold rests upon this rigid structure typically constructed out of soft steel such as S50C, P20 or, more expensively, 718, 1.2344 steel.

An important part of a mold is the mold cavity, Mold cavities play an essential part of molding; they determine both shape and size of molded parts. Hardened steel such as 718, 1.2738, NAK 80, 2344 or S136 is commonly used, often precision machined using high speed CNC or mirror EDM for flawlessness and defect-free results.

An injection mold’s core determines the internal shape and features of its finished part. A mold cavity, the outer portion that defines its external form, usually features more durable material for external shape creation. As another part of its mold half structure, core inserts may also be attached to something called core half which moves into position when closing up and forms its shape as you close down your mold half. As with all injection mold components, cores play an integral part in molding finished parts based on internal dimensions as well as any external features required by final product manufacturers.

Molten material enters a mold cavity via its sprue and runners. A gating system directs this flow with multiple gates such as side gates, pin point gates, direct gates, submarrine gates and channels; runners act as passageways from sprue to mold cavity via gates.

Molten material enters a mold cavity via its sprue and runners. A gating system directs this flow with multiple gates such as side gates, pin point gates, direct gates, submarrine gates and channels; runners act as passageways from sprue to mold cavity via gates. Plastic melt is injected through gates into an injection mold to start flowing outward, and its size and shape has an immediate impact on its final quality. Mold gates typically reside at the surface of mold cavities to evenly disburse molten plastic before molding begins; several varieties will likely be employed depending on material, size and shape requirements of part being produced.

Cooling systems help material solidify in molded parts while decreasing mold heat production, with cooling time typically accounting for 70 percent of every cycle. Therefore, their presence is absolutely key to effective injection molding processes.

Ejection systems are used to remove cool and solidified parts from mold cavities. Components in an ejection system include ejector pins, ejection bars, air ejectors, plates and more.

For complex movements or shapes in their parts, injection molds might also include slides or lifters in addition to these core components.